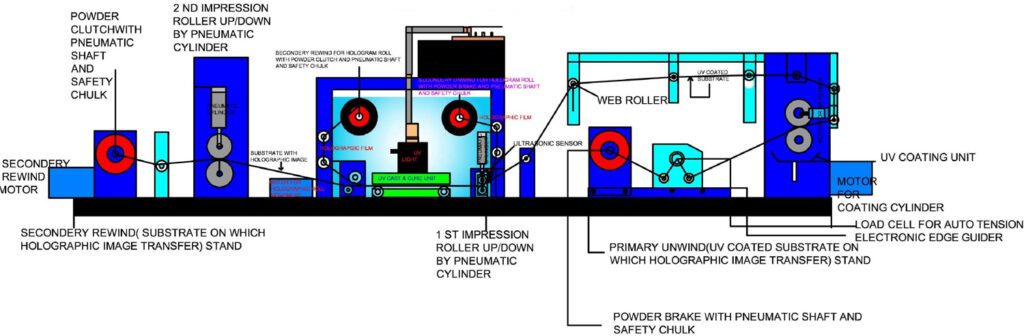

Detail Technical Specifications:

- Maximum Curing Width: 1020 mm

- Roll Dia: 600mm UV Coated Substrate Roll [Unwind & Rewind] & 275 mm max. for Holographic Roll.

- Primary Unwinding Unit: 20 KG Powder Brake with Load Cell Feedback Tension Controller. [Substrate] with Pneumatic Shaft & Safety Chalk Ultra Sonic Sensor Based Electronic Edge Guider.

- Primary Rewinding Unit: 20 KG Powder Clutch with Load Cell Feedback Tension Controller. [Substrate] with Pneumatic Shaft & Safety Chalk. Before rewinding there is one pneumatically operated nipping rubber roller for impression.

- Secondary Unwinding Unit: 10 KG Powder Brake with Tension Controller. [Hologram Roll] with Pneumatic Shaft & Safety Chalk

- Secondary Rewinding Unit: 10 KG Powder Brake with Tension Controller. [Hologram Roll] with Pneumatic Shaft & Safety Chalk

- UV Coating Unit: Coating through Gravure Process using coating Anilox and Rubber Roller for impression.

- Camera Controlled quality checking while embossing unit attached

- Curing Unit: 2 Nos. Mercury UV Curing Lamp Unit [395nm] with 30 Watt. per Sq. Cm curing capacity and 1200 mm curing width before curing there is one Impression Rubber Roller provided with pneumatic cylinder.

- After curing the Holographic Image Transfer on the Substrate.

- Pneumatic Unit: 4 nos. Pneumatic Cylinder included engaging /disengaging the Rubber Roller at first and second Impression Unit.

- Machine Drive Unit: 3 nos. Induction Motor attached with VFD Unit to run the machine properly.

- Machine Curing Speed : 75 Mtr./ Min Max

- Power Consumption: 415 VAC +/- 10%, 50Hz, 50KW Approx

- Weight: 1350 KG [Approx]

Drawings:

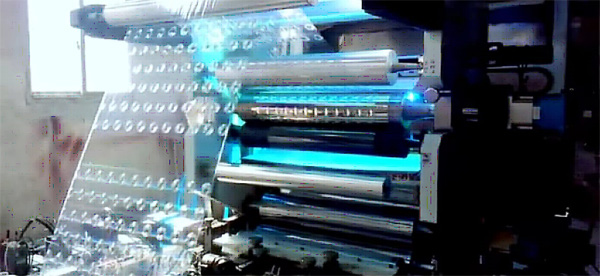

Machine photograph:

Machine video: